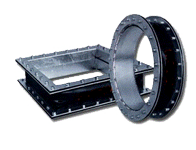

Non metallic Expansion Joints

Application

Fabric Expansion Joints are components for pipeline and machine constructions. They are capable, because of their material and shape, of compensating for movements, in addition to their sealing function. Fabric Expansion Joints are used in:

• Power plants;

• Chemical plants;

• Cement plants;

• Gas turbine plants;

• DeNOx plants;

• Incinerator plants;

• Steel plants;

• Dehydration plants;

• Ship building and marine technology.

Operational conditions

The good temperature reduction in the fastening areas, the following temperature-limits are possible:

- without insulation 400-500°C, and

- with insulation up to about 600-700°C.

With specialized construction, for example lining the interior with brick, Fabric Expansion Joints can handle temperatures up to 1000°C.

The permissible work diameter up to 5000 mm.

The technical problems caused by mechanical, chemical and thermal influences are solved economically by using a variety of materials in different combinations.

Advantages

• Highest flexibility and therefore the most allowance for movement with minimal installation height(pipeline distance).

• Reactive forces and adjusting forces are close to zero – for fixpoint calculations usually negligible.

• By using a variety of materials you can provide optimal and individual adaption to your working conditions.

• Cost effectively manufacture of large dimensions.

• Expansion compensation which leads to temperature differences

• Compensates for installation inaccuracies